Introduction

Choosing between ANSI Class 2 vs Class 3 safety vests is vital for your team. In fact, wearing the wrong gear is a major safety risk. Therefore, you must know the rules. Ultimately, this gear separates your workers from moving traffic.

According to OSHA Construction Standards, road workers must wear specific warning garments. However, the rules can be confusing. Specifically, the choice often depends on the speed limits of your job site.

We are here to simplify the ANSI/ISEA 107-2020 standard. By reading this guide, you will choose the right vest.

1. The Golden Rule: Traffic Speed

The quickest way to decide between these two ratings is simple. Look at the speed limit.

- Class 2 (Moderate Speed): Generally, use this where traffic flows between 25 mph and 50 mph.

- Use Cases: Airport workers, survey crews, and school crossing guards.

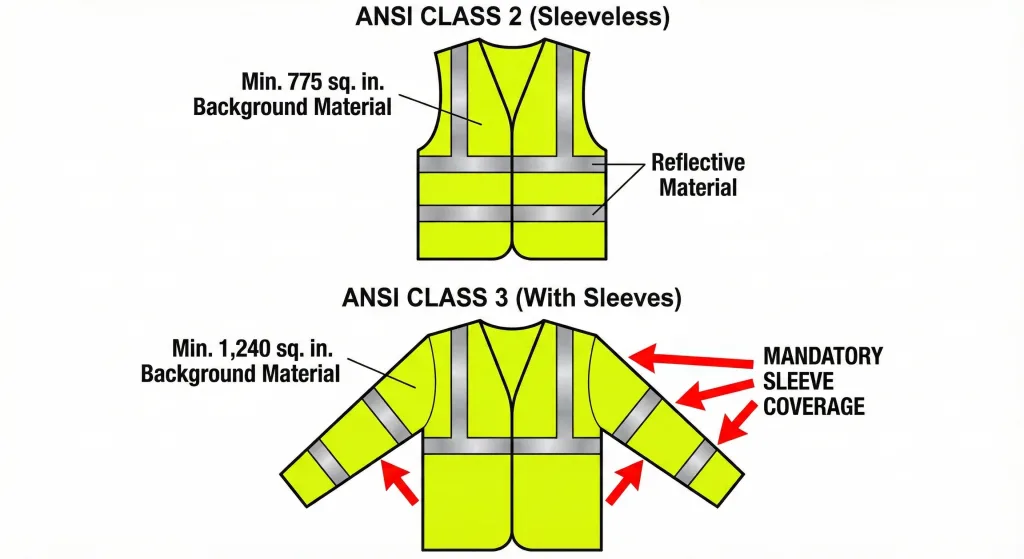

- Design: Typically, these are sleeveless vests. They are bright but do not need sleeves.

- Class 3 (High Speed): In contrast, Class 3 is mandatory for speeds over 50 mph.

- Use Cases: Highway construction and emergency responders.

- Design: Crucially, Class 3 gear must have reflective sleeves. As a result, the worker looks like a human, not a traffic cone.

2. ANSI Class 2 Vests: The Standard Choice

When comparing ANSI Class 2 vs Class 3, Class 2 is more common. Specifically, it requires 775 square inches of background fabric and 201 square inches of reflective tape.

Therefore, it is perfect for daylight work. It also works well if barriers separate you from cars. However, bad weather changes things. If fog or rain hits, Class 2 might not be safe enough.

3. ANSI Class 3: Maximum Visibility

On the other hand, Class 3 offers maximum visibility. Furthermore, it has reflective tape on the arms and shoulders. This creates a full “body silhouette.” Consequently, drivers recognize you instantly. They can see you from 1,280 feet away.

To meet this standard, the garment must have 1,240 square inches of background fabric and 310 square inches of reflective tape. This is why most Class 3 items are jackets or heavy shirts.

4. How to Upgrade: The “Class E” Trick

Many buyers do not know they can turn a Class 2 vest into a Class 3 ensemble. You do not always need to buy a heavy jacket. Instead, you can wear Class E Pants.

- What are Class E Pants? These are high-visibility trousers with reflective tape around the legs.

- The Math: Class 2 Vest + Class E Pants = Class 3 Suit.

- Why do this? In the summer, wearing a long-sleeve Class 3 jacket is too hot. By using cool Class E mesh pants with a Class 2 vest, you stay legally compliant without overheating.

5. Winter vs. Summer Gear

The battle of ANSI Class 2 vs Class 3 also depends on the season.

- Summer: Workers prefer the “Vest + Pants” combo mentioned above. It allows for airflow.

- Winter: A dedicated Class 3 Bomber Jacket is superior. It provides warmth, waterproofing, and instant compliance in one garment.

You can learn more about these testing methods at the International Safety Equipment Association (ISEA).

6. Do Safety Vests Expire?

A big question in the safety clothing debate is durability. Surprisingly, vests do expire. Specifically, the glass beads in the tape wear off.

- The Wash Label: Under the new ANSI/ISEA 107-2020 rules, manufacturers are no longer required to list a maximum number of washes (like “Max 25x”).

- The Visual Test: Instead, you must inspect the vest daily. If the reflective tape looks dull or the neon fabric has faded to a pale yellow, the vest is non-compliant and must be trashed immediately.

7. Frequently Asked Questions (FAQ)

Can I wear a Class 3 vest all the time? Yes. You can always use better protection. In fact, many managers mandate Class 3 for everyone just to be safe.

What is the difference between Type R and Type P? Type R stands for Roadway (construction). Type P stands for Public Safety (police). Generally, Type R vests are brighter and have more fluorescent material.

Are black safety vests OSHA compliant? No. A “black bottom” vest is fine if the top is neon. However, an all-black vest is not compliant. It fails the background material rules for ANSI Class 2 vs Class 3.

See the CDC NIOSH Highway Work Zone Safety guide for more details.

Conclusion

Choosing ANSI Class 2 vs Class 3 comes down to risk. Ultimately, if traffic is fast (>50 mph), you need Class 3. For slower zones, Class 2 is standard. To summarize, always check the label before you step onto the road.